Features of Chicken Essence Block Production Line

ZGH vertical high-speed mixer is an efficient mixer developed by our company, integrating advanced technologies from domestic and foreign sources. It has the following main features:

1. Due to the centrifugal force, the bottom feeding slurry continuously feeds the bottom material upward along the cylinder wall, while the upper material falls down from the center, creating a swirling circulation of materials.

2. The high-speed crushing slurry thoroughly crushes the chunky materials delivered by the feeding slurry.

3. Thanks to the high-speed rotation of the aforementioned slurries, the materials can achieve uniform mixing in a short period of time. The mixing speed uniformity are unmatched by other mixers in the domestic market. After mixing, there are no granular particles in the materials, achieving 100% uniformity.

4. The discharge valve can be opened for fast material discharge, and the equipment is easy to clean.

5. The contact parts of the machine are made of stainless steel, preventing material volatilization, deterioration, and loss during the mixing process.

6. During the mixing process, to ensure better sealing, our company uses bearings, anti-threaded caps, oil seals, and air seals to prevent material leakage caused by the shaking of the flying knife shaft and the gaps in the cylinder.

7. In the cleaning process, to prevent water leakage at the bottom,our company adds a raised labyrinth seal on the base and uses PTFE packing seal at the bottom, effectively preventing water leakage.

8. This machine is suitable for uniformly mixing dry and wet materials in different proportions, especially for stirring complex mixtures such as food powders, chicken essence, pharmaceutical powders, and beverage powders.

Working Principle:

The ZGH vertical high-speed mixer consists of a bottom feed slurry and a high-speed cutting slurry. The bottom feed slurry continuously feeds the materials along the cylinder wall upwards. The high-speed cutting slurry thoroughly crushes the materials brought by the feed slurry. This creates a swirling effect, allowing the materials to circulate and achieve uniform mixing in a short period of time.

Technical Parameters

1. Mixing capacity per batch: 300 kg

2. Stirring speed: 180 rpm

3. Cutting speed: 1440

4. Cutting motor power: 3 kW

5. Stirring motor power: 22 kW

6. Dimensions (mm): 1900x1050x1500

YK-160 Oscillating Granulator

Main application:

This machine is used mainly in such trades as pharmacy, chemical industry, food, pottery and plastics extensively, making moist powder material particle. Make cylinder swing reciprocatly, extruding material from screen mesh for granulation.

Technique Parameter:

| Model | YK-160 |

| DIA rotor(mm) | 160 |

| Capacity (kg/h) | 200-300 |

| Rang of wave | >360° |

| Number of times of waving rolingly | 55 |

| Motor power(kw) | 2.2 |

| Weight (kg) | 260 |

| Overall size(mm) | 970*560*1240 |

ZP15D Rotary tablet press

1. The main advantages of the ZP15D rotary tablet press:

The ZP15D rotary tablet press is the latest developed fully enclosed dual-color tablet press. It has the following features: high working pressure, reasonable structure, simple operation, high productivity, stable and reliable operation, convenient installation and maintenance, beautiful appearance, no dust flying, and low noise. It is a basic equipment used in pharmaceuticals (especially herbal preparations), chemical industry, food industry, electronics, plastics, powder metallurgy, and other industrial sectors to compress various dry granular materials into round or irregular tablets. It is particularly suitable

for the production of various batch and multi-variety tablets.

2. The main machine structure of the ZP15D rotary tablet press:

The upper half of the machine is the compression chamber, which allows for clear observation of the compression process. It is equipped with a reasonable suction system, which ensures that floating dust is eliminated from all directions.

3. Main Parameters and Configuration List of ZP-15D Rotary Tablet

| Main Parameters |

| Name | Specification/Model/Unit | Remarks |

| Number of Dies | 15 sets |

| Maximum Tablet Compression Force | 150 kN |

| Maximum Tablet Diamete | 32 mm |

| Upper and Lower Punch Diameter | 32mm |

|

|

| Upper and Lower Punch Length | 117×115mm |

| Middle Die Diameter | 45mm |

| Middle Die Thickness | 40mm |

| Maximum Rotation Speed of Turntable | 25 rpm Frequency Conversion Adjustment |

|

|

| Production Capacity | Dual Tablet Output: 30,000 tablets/hour |

| Machine Noise | Idle: 60 decibels Loaded: ≤80 decibels |

| Machine Dimensions | 930×900×1700mm |

| Machine Net Weight | 1650kg |

| Electric Motor | ModelY112M-4 | Jiangsu Daye |

| Power7.5KW |

| Speed 1440rpm |

| Frequency Converter | Frequency Converter11KM |

|

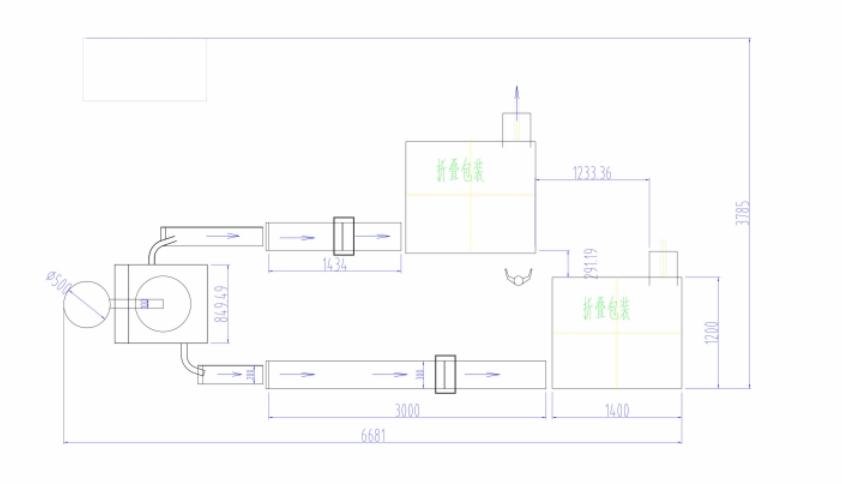

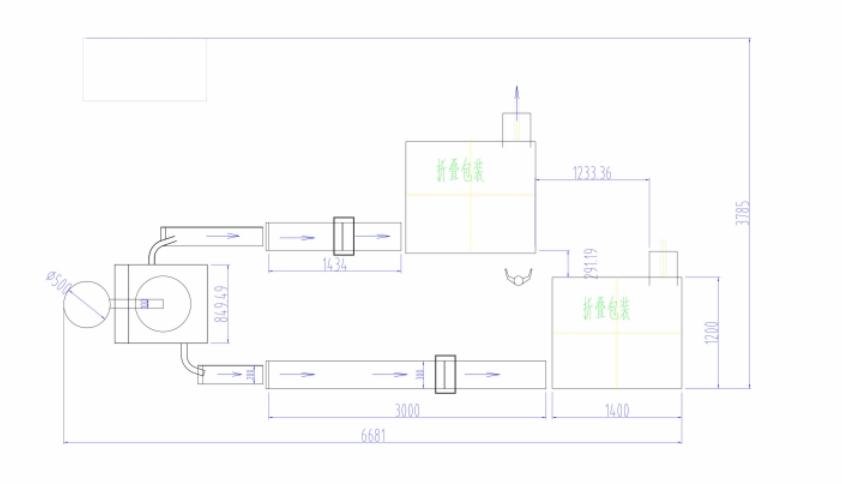

Fully automatic belt feeding packaging line

YRB-600 Automatic high-speed folding packaging machine

Machine Overview

This machine offers various packaging options (sealed, edge sealed, twisted), with speeds of up to 600 pieces per minute depending on the packaging method and material variations. It adopts servo tracking technology, ensuring accuracy and stability, and can automatically adjust speed based on the material.

Main technical parameters

1. Power:0.75KW / 220V

2. Machine Weight:1300 ㎏

3. Packaging Speed:600 packs per minute

English

English français

français Español

Español русский

русский português

português العربية

العربية