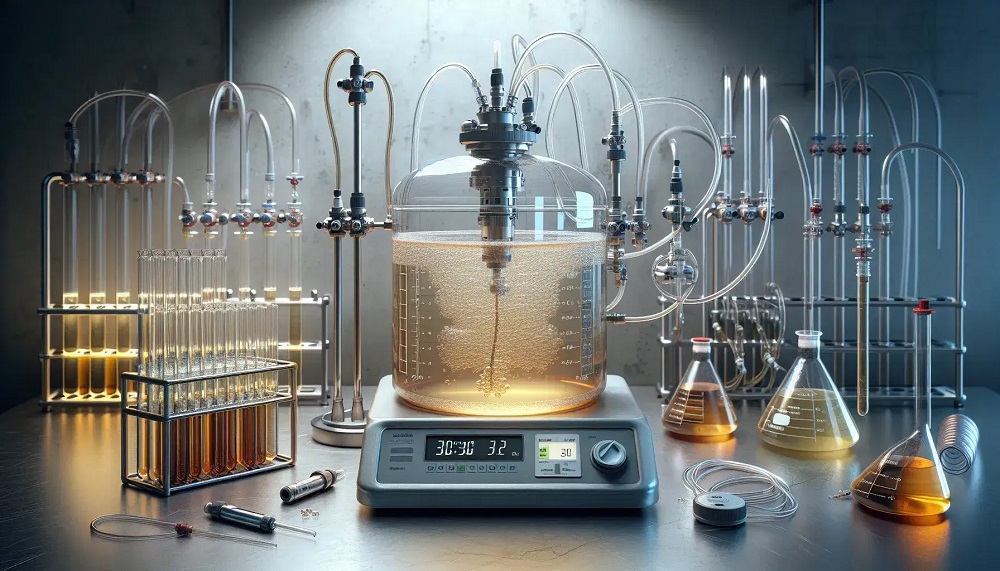

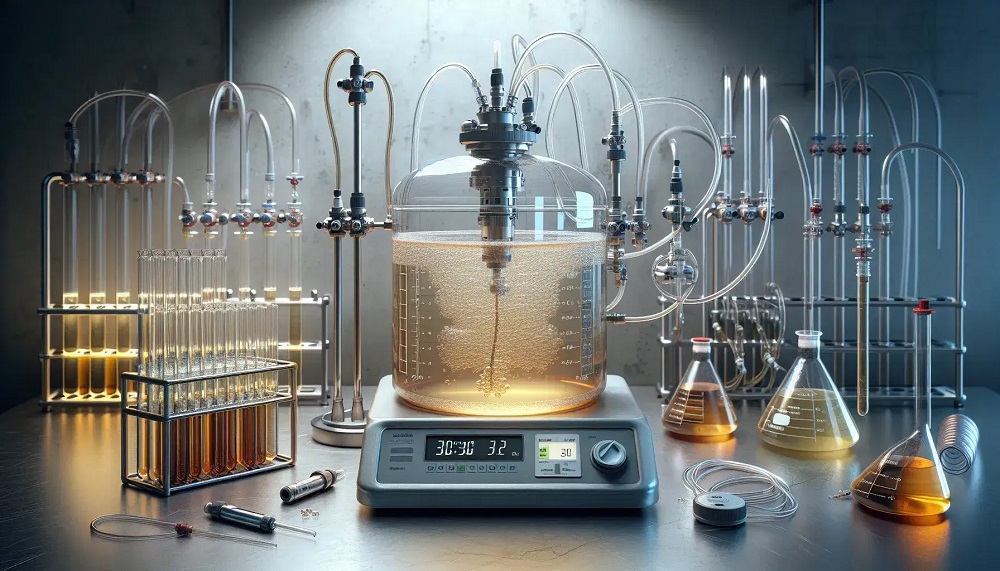

Fermentation broth is a complex multiphase system. The composition of fermentation broth after microbial fermentation with microbial fermentor is usually complex, most of which is water, followed by microbial or animal and plant fragments and a small amount of unused culture medium. In addition, there is a certain amount of metabolites. The presence of these substances may affect the filtration effect.

1. Main characteristics of fermentation broth:

What is fermentation broth? Understanding these characteristics of fermentation broth is of great significance for selecting appropriate filtration methods and membrane filtration equipment and optimizing filtration processes. In actual operation, corresponding measures need to be taken according to specific circumstances to obtain high-quality target products. Generally speaking, the characteristics of fermentation broth are mainly manifested in the following aspects:

(1) Complex composition: Fermentation broth is a multiphase system containing two phases, solid and liquid. Among them, the solid components include bacteria and unused solid culture medium, and the liquid components include a large amount of water and other substances dissolved in water. In addition, the fermentation broth may also contain other substances such as suspended matter, particles, proteins, metal ions, etc.

(2) Low concentration of target product: The concentration of target product in fermentation broth is usually low, mostly 1%-10%, which is also an important characteristic of fermentation broth filtration. Since the concentration of the target product is low, other impurities and interfering substances need to be removed as much as possible during the filtration process to obtain a high-purity target product.

(3) Contains a large amount of water: The fermentation broth usually contains a large amount of water, which is because a large amount of water is required during the growth and metabolism of microorganisms. Therefore, a large amount of water needs to be removed during the filtration process to obtain a high concentration of the target product.

(4) May contain particles of different sizes and shapes: The fermentation broth may contain particles of different sizes and shapes, which may be caused by bacterial lysis, solid culture medium decomposition, etc. These particles may affect the filtration effect, so they need to be treated or removed.

(5) Contains biologically active substances: The fermentation broth contains many biologically active substances, such as enzymes, cytokines, etc. These substances may affect the filter medium, so attention should be paid to the selection and treatment of the filter medium during the filtration process.

2. Pretreatment methods of fermentation broth:

2.1. Reduce liquid viscosity

Reducing liquid viscosity can be achieved by heating and diluting with water. The heating method is to reduce the viscosity of the fermentation broth by heating it. Increasing the temperature of the fermentation broth can effectively reduce the viscosity of the liquid, and the protein will also coagulate to form large particles of coagulants, and the filtration characteristics of the fermentation broth have been further improved. However, the heating temperature and time need to be strictly controlled to avoid affecting the activity of the target product and cell autolysis. The water addition method is to reduce the viscosity of the fermentation broth by adding water to dilute it. This method can reduce the viscosity of the fermentation broth to a certain extent, but at the same time it will increase the volume of the fermentation broth and reduce the concentration of the target product, which needs to be weighed according to the actual situation.

2.2. Adjusting the pH value

The filtration characteristics can be improved by adjusting the pH value. Amphiphilic substances such as amino acids and proteins can be precipitated and removed at the isoelectric point. By changing the ionization degree and charge properties of the substance, the solubility of substances such as microbial cell walls and proteins is affected, thereby optimizing the filtration characteristics. During membrane filtration, adjusting the pH value can change the charge properties of easily adsorbed molecules and reduce membrane clogging and contamination. At the appropriate pH value, cells, cell fragments and certain colloidal substances will tend to flocculate and form larger particles, which is conducive to the filtration operation.

2.3. Adding reactants

Adding reactants and certain soluble salts to the fermentation broth does not affect the target product, and can react with impurities to form insoluble precipitates, which can eliminate the influence of certain impurities in the fermentation broth on filtration and improve the filtration rate. Such as CaSO4, AlPO4, etc. The generated precipitate can prevent the mycelium from sticking together, making the mycelium have a block structure. The precipitate can also be used as a filter aid, and can solidify colloids and suspended matter to improve filtration performance. In the fermentation products with polysaccharides as carbon sources, the fermentation broth contains insoluble polysaccharides, which are converted into monosaccharides by enzymes to increase the filtration rate.

2.4. Adding filter aids

The suspended matter such as bacterial cells and coagulated proteins in the fermentation broth is often small and easy to deform. Direct filtration can easily cause the filter holes of filter media such as filter cloth to be blocked, resulting in filtration difficulties. In order to improve the speed of the fermentation broth, filter aids are usually added during the pretreatment of the fermentation broth. Filter aids are incompressible porous particles that can loosen the filter cake and increase the filtration rate. A large number of fine colloidal particles in the suspension are adsorbed onto the surface of the filter aid, changing the structure of the filter cake. The resistance to filtration is reduced. Commonly used filter aids include non-metallic minerals such as diatomaceous earth, perlite powder, activated carbon, quartz sand, asbestos powder and clay. And organic matter such as cellulose (such as sawdust, sugarcane core) starch. Mineral filter aids have good filtering effects. But they affect the comprehensive utilization of filter cakes. For example, the protein content is reduced after the addition of mineral filter aids to the bacterial filter cake. There are generally three ways to use filter aids: one is to pre-coat the filter aid on the surface of the filter medium, the other is to add it directly to the fermentation liquid, or both methods can be used at the same time. When selecting and using filter aids, the type, particle size and addition amount of the filter aid should be selected according to the target product, filter medium and filtration conditions.

2.5. Coagulation and flocculation

The use of coagulation and flocculation technology can effectively change the dispersion state of cells, cell fragments and dissolved macromolecules, destroy their stability, and make them aggregate into larger separable particles to increase the filtration rate and facilitate separation; at the same time, it can also effectively remove impurities such as proteins and solid impurities and improve the quality of the filtrate. Flocculation refers to the process of forming coarse floccules of colloid particles based on bridging in the presence of certain polymer flocculants. It is a process based on physical aggregation. Flocculant is a water-soluble polymer with a relative molecular weight of tens of thousands to ten million. It has a long chain structure and contains many active functional groups on its chain links. It is strongly adsorbed on the surface of colloid particles through electrostatic attraction, van der Waals force or hydrogen bonding. Coagulation refers to the phenomenon that the colloidal system becomes unstable due to the reduction of the double layer repulsion potential under the action of neutral salt. When a certain electrolyte is added to the colloidal suspension, the potential decreases due to the reduction of the double-layer electrical repulsion between the colloidal particles under the action of the hetero-charged ions of the electrolyte, making the colloidal system unstable (destabilized). The colloidal particles collide with each other and aggregate into 1mm-sized aggregates.

The factors that affect the flocculation effect are as follows:

(1)Type and dosage of flocculant: The type and dosage of flocculant will affect the flocculation effect. Different types of flocculants have different mechanisms of action and scope of application. It is necessary to select the appropriate type of flocculant according to the actual situation. At the same time, the dosage of flocculant will also affect the flocculation effect. Too little or too much flocculant will have an adverse effect on the flocculation effect.

(2)Reaction time and temperature: The reaction time and temperature of the flocculant and the fermentation liquid will also affect the flocculation effect. Generally speaking, the flocculation reaction takes a certain amount of time to complete. Too short a reaction time may result in insufficient flocculation. At the same time, temperature will affect the activity and reaction rate of the flocculant. Too high or too low a temperature is not conducive to the flocculation effect.

(3)Characteristics and composition of the fermentation broth: The characteristics and composition of the fermentation broth will also affect the flocculation effect. The pH value, ionic strength, size and shape of suspended particles in the fermentation broth will affect the flocculation effect. In addition, macromolecular substances such as proteins and polysaccharides present in the fermentation broth may also affect the flocculation effect.

(4) Mechanical stirring and filtration conditions: Mechanical stirring and filtration conditions are also important factors affecting the flocculation effect. Appropriate mechanical stirring can promote the dispersion and adsorption of flocculants in the fermentation broth and improve the flocculation effect. The filtration conditions will affect the separation and collection of the flocculation products, and inappropriate filtration conditions may lead to poor flocculation effect. In short, no matter whether the product we need is intracellular or extracellular, we must first pretreat the fermentation broth and use solid liquid separator before proceeding with subsequent operations. The above methods have their own characteristics, and usually several methods are used in combination to improve the efficiency of fermentation broth pretreatment.

English

English français

français Español

Español русский

русский português

português العربية

العربية Deutsch

Deutsch tiếng việt

tiếng việt 한국어

한국어 Türkçe

Türkçe Malay

Malay