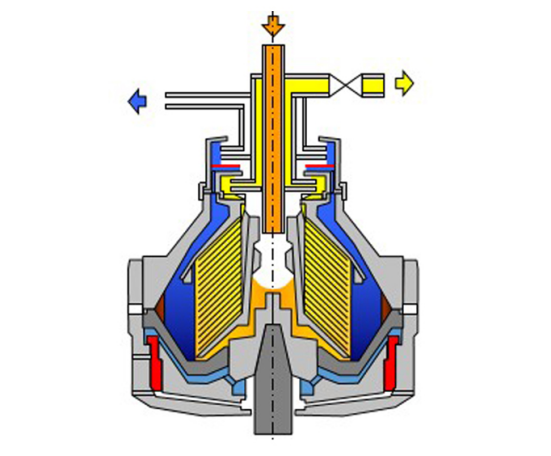

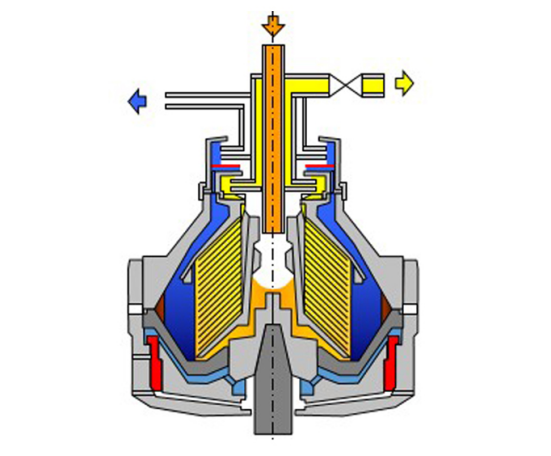

1. Principle of Disc Centrifuge:

There is a group of discs stacked together in the drum of the disc centrifuge. The suspension is added to the drum from the feed pipe located in the center of the drum. When the suspension flows through the gap between the discs, the solid particles (or droplets) settle on the discs under the action of the centrifuge to form sediment (or liquid layer). The sediment slides along the surface of the disc and detaches from the disc and accumulates in the part with the largest diameter in the drum. The separated sediment (or liquid layer) is discharged from the drum from the liquid outlet. The function of the disc is to shorten the sedimentation distance of solid particles (or droplets) and expand the sedimentation area of the drum. The installation of discs in the drum greatly improves the production capacity of the separator. The solids accumulated in the drum can be discharged from the drum through the slag discharge hole without stopping the machine. The addition of discs to centrifuges is a major breakthrough innovation in the history of centrifuge development.

2. Application Fields:

Solid-liquid separation of materials with a wet weight of less than 30% and a particle diameter greater than 0.5μm: clarification of microbial fermentation and mammalian cell culture fluid; clarification of fruit juice and separation of beer in food; separation and clarification of materials in fermented brewing products; centrifugal separation of vaccines, mycelium, antibiotics, and vitamins in pharmaceuticals.

3. Application Characteristics:

The biggest feature of the disc centrifuge is its high degree of automation and low labor intensity. It can realize continuous feeding and automatic discharging of materials with low labor intensity. Compared with the labor intensity of tubular centrifuge machine during use, which is close to that of construction workers, the labor intensity of the equipment during use is close to that of white-collar beauties drinking coffee while working.

Material handling capacity. The specific processing speed needs to comprehensively consider factors such as the wet solid content, viscosity, and particle size of the material, and needs to be properly optimized during the test;

The disc centrifuge has a relatively large centrifugal force and a relatively high separation factor. For most fermentation broths, centrifugation can obtain a wet bacterial solution with low water content. For clarification and separation of materials with high solid content (greater than 5%), disc centrifuge is preferred.

English

English français

français Español

Español русский

русский português

português العربية

العربية