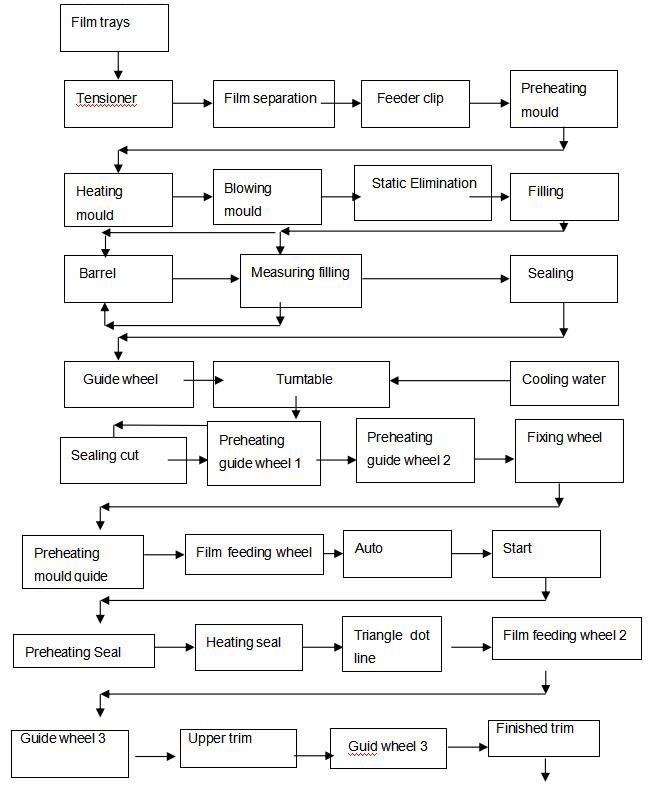

The automatic suppository filling production line has a stable and efficient manufacturing process, forming, filling, freezing, sealing and other production processes to complete the whole process, and the production capacity is 1,000-23,000 grain/hour. As a leading and professional pharma machine supplier, we offer quality types of suppository making machines for you to choose from, competitive factory price. If you are interested, welcome to contact us to get further infomation.

-

Products

- Bioreactor Fermenter

- Centrifuge Separator

-

Suppository Production Line

- Sinotech 15Model Suppository Making Machine

- suppository filling and sealing machine with 1 filling head

- Full-automatic Suppository Production Line SJ-2L

- Suppository filling machine

- Suppository Filling And Sealing Machine

- 6 Heads Suppository Forming Machine

- 7 Filling Heads Continuously Automatic Suppository Production Line

- Lab Type Semi Suppository Filling And Sealing Machine

- SJ-1LB Lab Semi Suppository Production Line

- Soft Gel Production Line

-

Tablet Press Machine

- Zp29/31/33 Multifunction Herb Tablet High Speed Double Sided Tablet Press

- Hydraulic Tablet Press

- Medical Tablet Press Machine

- Salt Tablet Press Machine

- Candy Tablet Press Machine

- Tablet Press Punch Die TDP Mold ZP Mold

- Big Size Two Layer Double Color Dishwashing Tablet Automatic Rotary Effervescent Tablet Press Machine

- Thp Series Big Flower Basket Tablet Press Machine

- ZP-31D Rotary Tablet Press

- ZP-45D Rotary Tablet Press

- ZPW-17D Rotary Tablet Press

- ZPW-23 Three Layer Press Machine

- Single Punch Tablet Press

- ZP15D 17D 19D Rotary Tablet Press

-

Capsule Filling Machine

- NJP200 Capsule Filling Machine

- NJP400 Capsule Filling Machine

- NJP600 Capsule Filling Machine

- NJP800 Capsule Filling Machine

- NJP1200 Capsule Filling Machine

- NJP2500 Capsule Filling Machine

- NJP3800 Capsule Filling Machine

- Cgn-280-D Semi-Automatic Capsule Fill Machine

- NJP7500 Capsule Filling Machine

- CE Pharmaceutical Hard HPMC/Gelatin/Halal/Vegetarian/Hollow/ Pullulan/Empty/Hard/Vegetable/Clear Capsules Filling Packing Machine/Encapsulation Machine

-

Blister Packing Machine

- YD-420F Model Surprise Egg Blister Packing Machine

- DPH-260 Model High Speed Blister Packing Machine

- DPP-270S Blister packing machine (blister with paper card)

- DDP-140 Automatic Electric Blister Packing Machine for Tablet Pills Capsule

- Tablets Automatic Alu-pvc Blister Packing Machine

- DPP 80 Automatic Jam Honey Blister Packaging Machine with Peristaltic Pump

- DPP-80 Automatic Aluminum Plastic Blister Packing Machine Capsule Blister Packing Machine

- Full Automatic Oil Liquid Blister Packaging Honey Chocolate Sauce Cream Syrup Food Jelly Blister Packing Machine

- Fully Automatic Butter Cheese Paste Cream Blister Packing Machine

- Desktop Blister Sealing Machine

-

Pill Counting Machine

- Automatic 16 Channel Vibration Intelligent Visual Capsule Counting Machine

- Pharmaceutical Grade Tablet Pill Counting Machine

- Multi Channel Automatic Vibrating Bottle Capsule Counting Machine

- Automatic Candy Bottle Counting Machine

- Benchtop Tablets Capsules Pills Counting Machine

- Yl-2A Desktop Small Electronic Tablet Counter

- Freeze Dryer

- Spray Dryer

- Membrane Filtration Equipment

-

Filling Machine

- SINOTECH250-B Automatic Tube Filling and Sealing Machine

- SINOTECH350-B Model Automatic Plastic Tube Filling and Sealing Machine

- Fully Automatic Filling Sealing Machine for Plastic Toothpaste Tube Soft Cosmetic Cream

- Single filling head YD300A--automatic Cartridge filling machine

- 200L Hydraulic Extruder --(KINGPACK MACHINERY)

- Coffee Capsule Filling and Sealing Machine

- High Speed Linear Type Coffee Capsule Filling and Sealing Machine

- DJ-50D multifunctional vertical box filling machine

- SINOTECH-60S Automatic Aluminum tube filling and Sealing Machine

- Project

- Company

- Application

-

Services

- Blog

- Resources

- Contact

English

English français

français Español

Español русский

русский português

português العربية

العربية