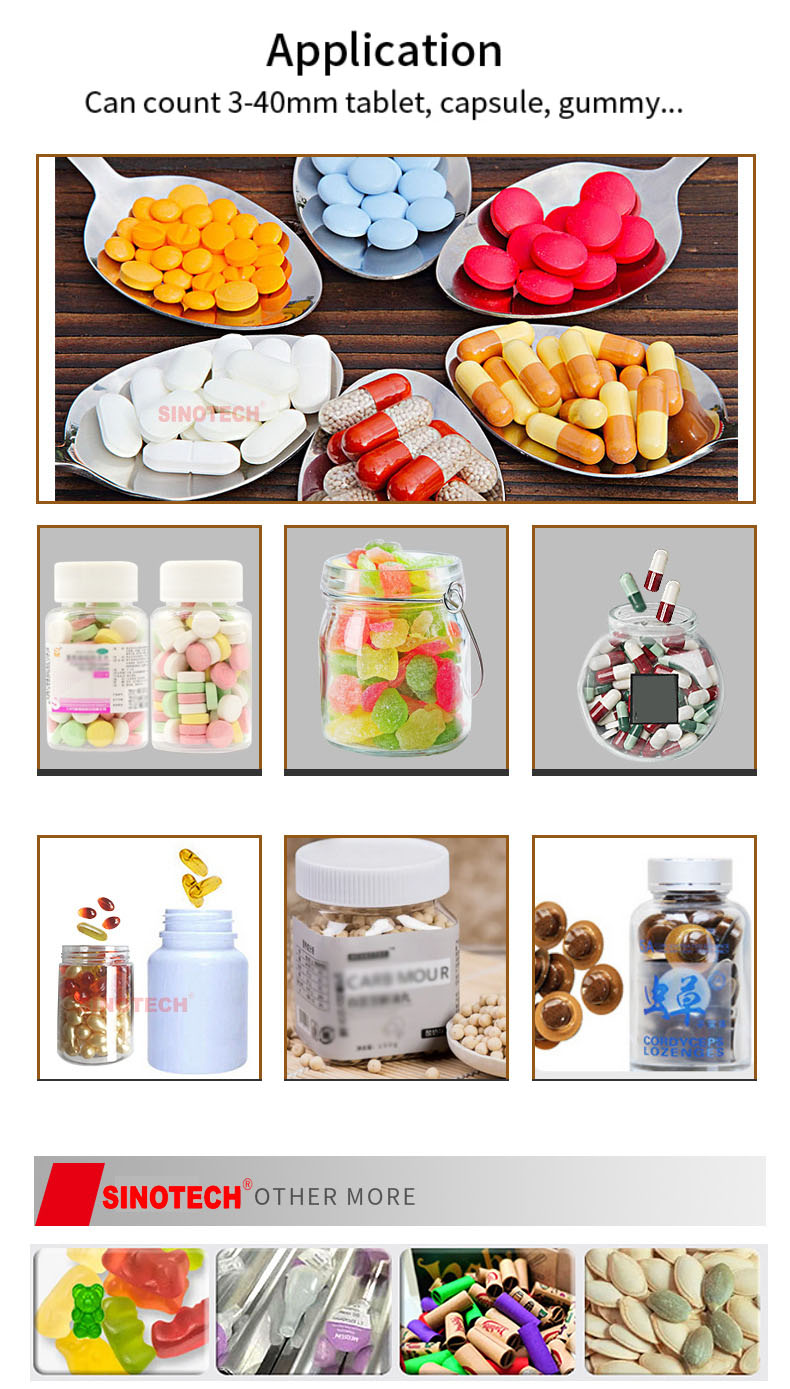

1. Wide applicability, used for tablets (including abnormal tablets), capsules, gels

(including abnormal gels, transparent gels and opaque gels) pills and most solid

granules.

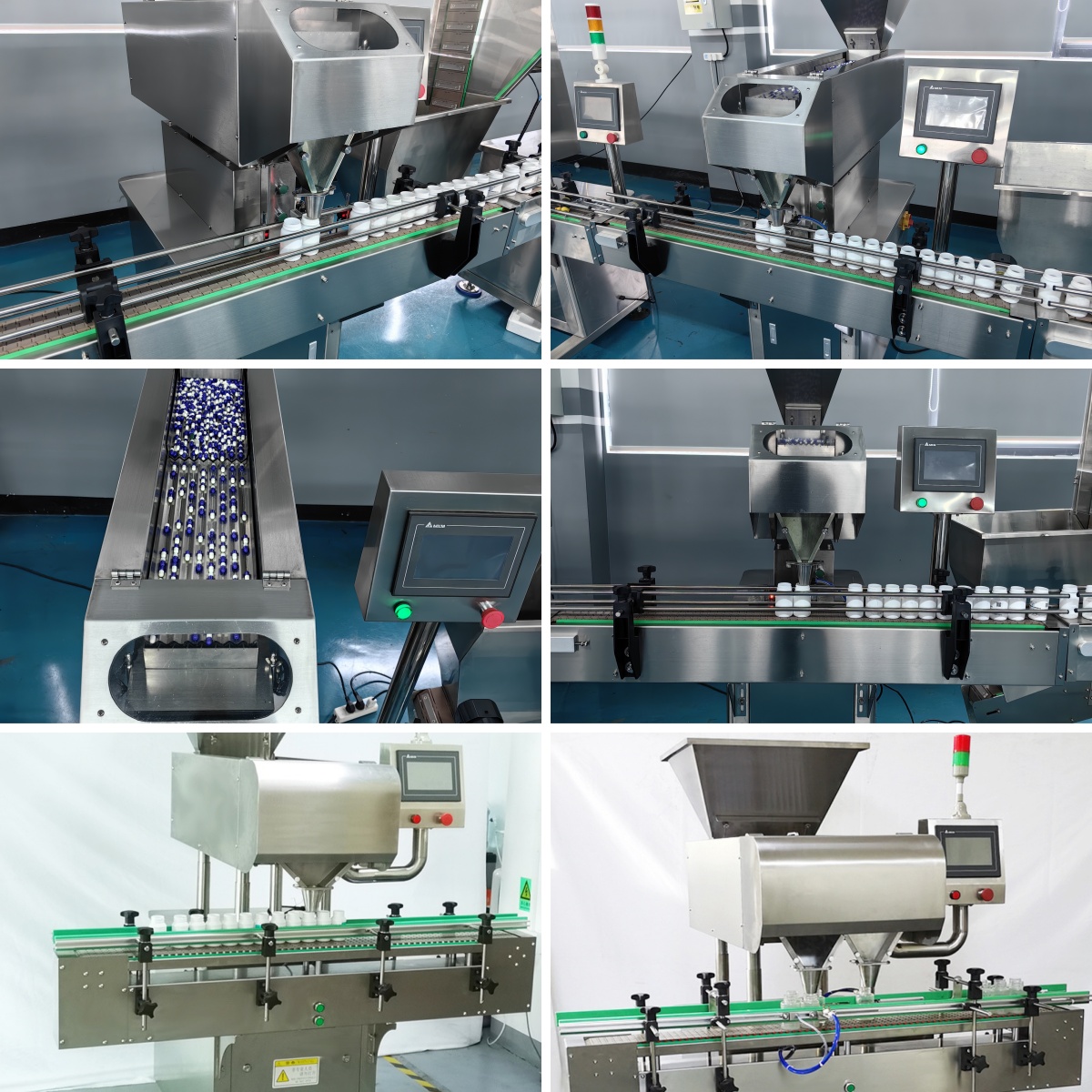

2. 16 tunnels vibration feeding, special patent filling part, feeding evenly, no breakage of

the material

3. Anti-dust, using our own original high anti-dust sensor technology, the machine works

accurately with good stability in heavy dust conditions.

4. Count accurate: photoelectric sensor automatic counting and bottling error is less than

the national standard

5. Hopper mouth of the special structure, to prevent the materials jam, small mouth

bottle can quickly bottling.(Optional)

6. High-degree of automatic, no bottle will not count and fill. Automatically remove bottles

of filling abnormalities and a certain size broken tablets. Self-diagnose errors and stop

working to make alarm at errors.

7. Supporting functions: lack of bottle of photoelectric sensor automatically detection,

automatically stop

8. Easy to operate: Using intelligent design, in Chinese or Chinese-English menu, various

operation parameters according to the need to set, can store 10 groups set parameters,

in order to use

9. Easy to Maintenance, workers can work with simple training, easy to remove、clean、

change parts, and no need tools

10. Sealing dust proof, with dust-remove box, reduce dust pollution.(Optional)

English

English français

français Español

Español русский

русский português

português العربية

العربية