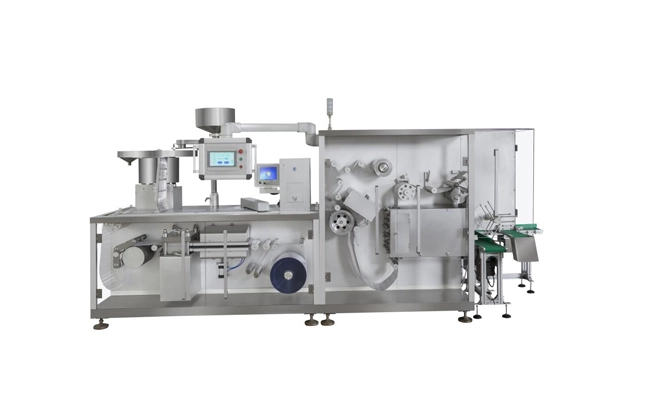

Advantages of DPH-260 Model High Speed Blister Packing Machine

Product design concept, advantages and new technology application. This product design concept: with the increase of personnel flow, labor cost, maintenance force decline in pharmaceutical enterprises, product design and improvement toward the direction of "digital intelligence" development, it requires high degree of automation, high efficiency, high stability, simple maintenance, low maintenance cost. When this machine is put into the market, it is called: digital intelligent equipment.

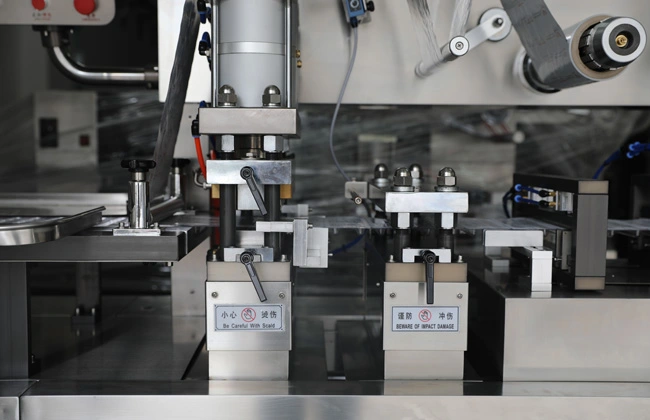

1. Strong Forming Pressure

This product design concept: with the increase of personnel flow in pharmaceutical enterprises, labor costs, maintenance force decline, product design and improvement toward the "silly" direction development, it requires a high degree of automation, high efficiency, high stability, simple maintenance, low maintenance cost. For this reason, when the machine was put on the market in 1998, it was called: silly melon machine. It absorbs the advantages of drum type (DPT) and flat type (DPP). The quality of bubble forming depends on the forming part. The forming device of most domestic manufacturers is single eccentric wheel of cast iron, and the bearing is easily broken and is not easy to be removed after it is broken. Our company adopts the hyperbolic double CAM structure, force balance, design pressure 10T, the forming device for the whole stainless steel structure, not bad for 10 years. (because the PVC theoretical forming pressure is 1.29T, according to the PVC national standard stipulate ±0.07mm/mm2 is qualified, the difference within 1mm2 PVC can be 0.14mm. Before forming, forming pressure must be leveled PVC to ensure good forming, 4-8T forming pressure is far from enough).

2. Fully Servo Structure

Five sets of servo motors and servo drives are used for traction step, punching step and punching cutter drive and sealing foil rewinding step.

Features: ensure synchronization, servo traction, equal division, encoder adjustment, there will be no deviation in punching; the blister keeps integrity during embossing and cutting, good position and accurate.

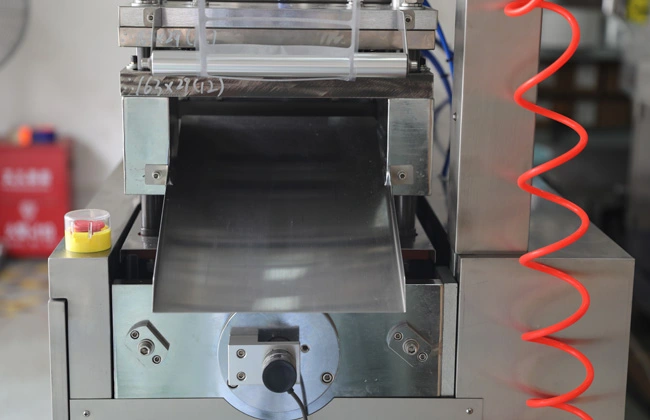

3. Aluminum foil constant tension control

The output of constant tension pulls the aluminum foil for heat sealing by the tension detector, avoid the change of coil diameter and the change of tension, greatly reduce the probability of aluminum foil wrinkle (aluminum foil never wrinkle), ensure the quality of heat sealing.

4. Roller plate structure

Flat plate forming ensures bubble forming is hard and bright; and rolling heat sealing structre, ensures light pressure, good sealing effect and fast speed.

5. Buffer type batch number embossing and perforation line, using large camshaft and large bearing, the batch number embossing is more powerful and stable.

6. Segment type batch number embossing and buffer perforation, high efficiency, stability, fine and beautiful line, easy to tear.

Independent batch number adjusting mechanism, convenient to adjust the clarity of batch number, abandon 0ld type, adopt the whole stepped steel structure, more convenient and quick.

7. PID heating and manual adjustment mechanism

PID heating control temperature accurate and protect the heater life, similar to energy saving lamp pulse heating, the service life of at least 4 years, using flow type imported plane coating, more wear-resistant, more uniform heat conduction, less error.

Adopt adjustable heating plate mechanism, no matter large mold or small mold, all step in place, no need to repeatedly disassemble, replace the mold is more efficient.

8. Eye marking system can be choose for optional.

The eye marking system helps the content to be comprehensive, effectively guide patients to use the drug correctly, and the product is more beautiful.

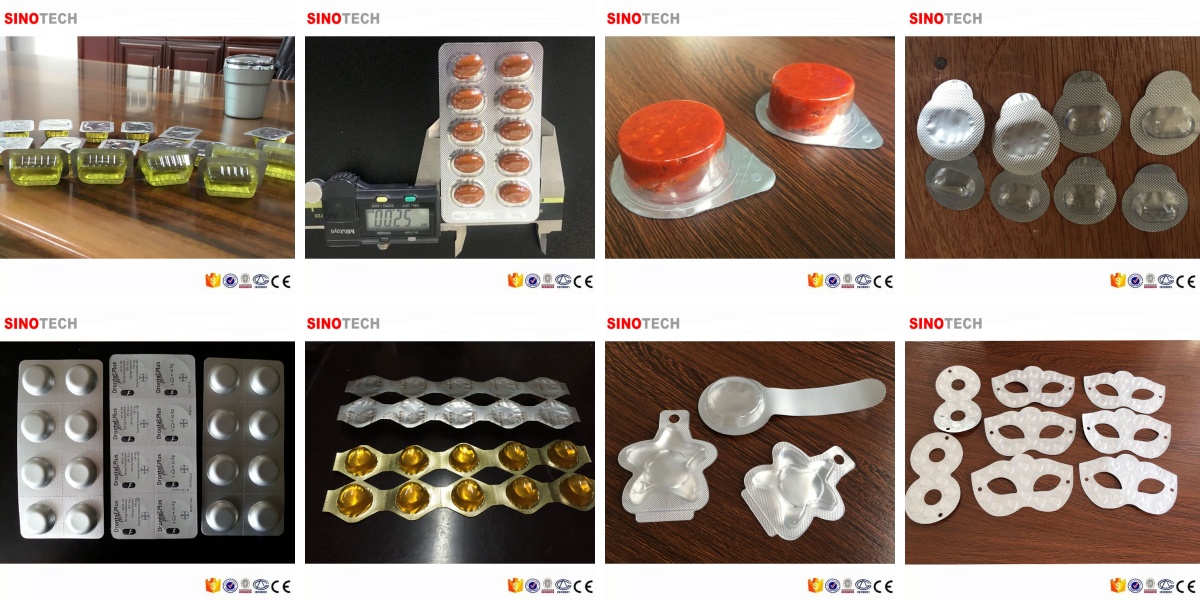

10.Can be used for both alu-alu and alu-pvc

Only need to change the mold (the mold adopts the card groove structure, no need positioning, adjustment, no need to plug the cooling water pipe, the mold can be pushed into), can adapt to a variety of packaging materials, to ensure the rapid exchange of multiple varieties.

11. Quick variety change

The innovative design of groove stepping die and split forming die can reduce 70% time, no adjustment, automatic tracking, greatly shorten the time of changing mould and reduce the technical requirements of operators. To ensure the rapid exchange of multiple varieties. The heat sealing controlled by servo, no matter the plate size change, the variety change without changing the sprocket.

12. Three-stage dust removal and static electricity removal for optional (mainly for tablets without coating)

Remove excess dust from the feeding and PVC part to avoid incomplete heat sealing which will affect the appearance of the plate.

13. Vibrating feeder

Our device is not only suitable for capsule,round tablet feeding, but also can suitable for the square tablet, oblong tablet and so on. And extrally screening vibration feeding to achieve dust-free packaging.

High speed special feeder, to ensure that the feeding rate of the equipment always keep up with the aluminum plastic PVC molding speed.

To avoid insufficient feeding rate so as affect the overall punching frequency of the equipment.

Stable, efficient, no damage to the material, without manual intervention.

Vibrating feeder

14.Secure partition management

The machine is divided into five independent areas: 1. The filling area is easy to clean. 2. Forming area. 3. Sealing and cutting area. 4. forming the chassis. 5. Electrical control area. Controlled by servo motor, each area can be started separately.

15.Wide operation platform structure: convenient operation, reduce labor intensity.

16.Intelligent control system

The use of multiple servo system precision control, so that the production, operation, maintenance more labor-saving. Full data operation mode, can upload production data and remote communication, a large number of help and self-check system, to ensure the safety of users and equipment.

English

English français

français Español

Español русский

русский português

português العربية

العربية